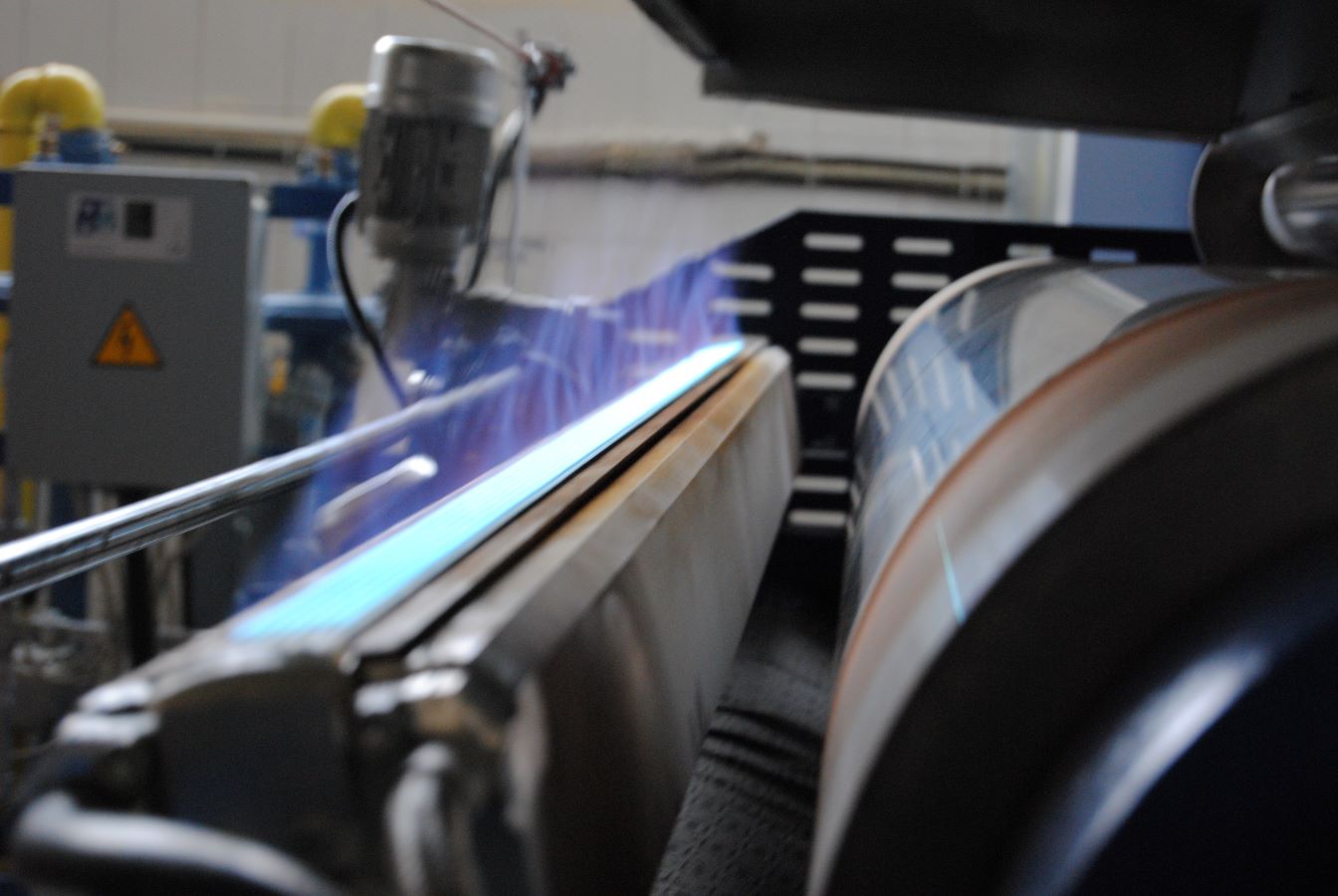

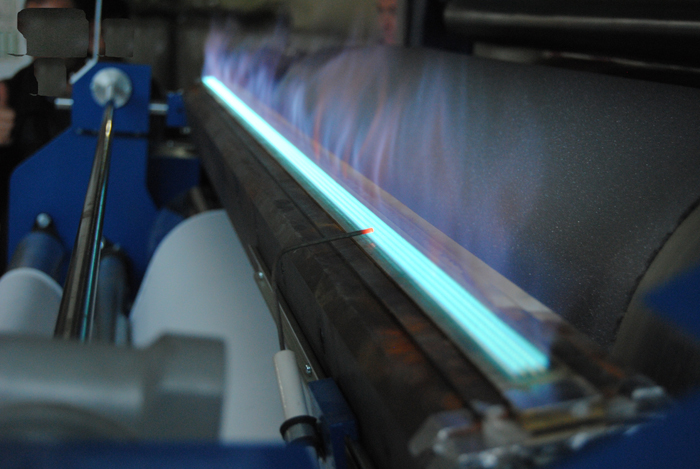

offers a diverse range of flame lamination machines, catering to various production needs. Starting from compact units, equipped with just one burner, to highly advanced continuous operation lines boasting significant production capacities.

Our machines are fully customizable to meet both your current requirements and future expansions.

Mechanical speed: 2 – 60 mt/min

- Power: 400 V/50 Hz/triphase

- Useful working width: from 1200 up to 2400 mm

In addition to our machinery offerings, we provide comprehensive support, including:

- Adaptations of your production site

- Installation of machinery and supporting systems

- Training for your production staff and maintenance teams

- Assistance with sourcing suitable raw materials

- Machinery settings and production parameter guidance

- Exploration of potential applications

At Lamitoo, we are committed to ensuring your success every step of the way.