Here's an overview of embossing technology:

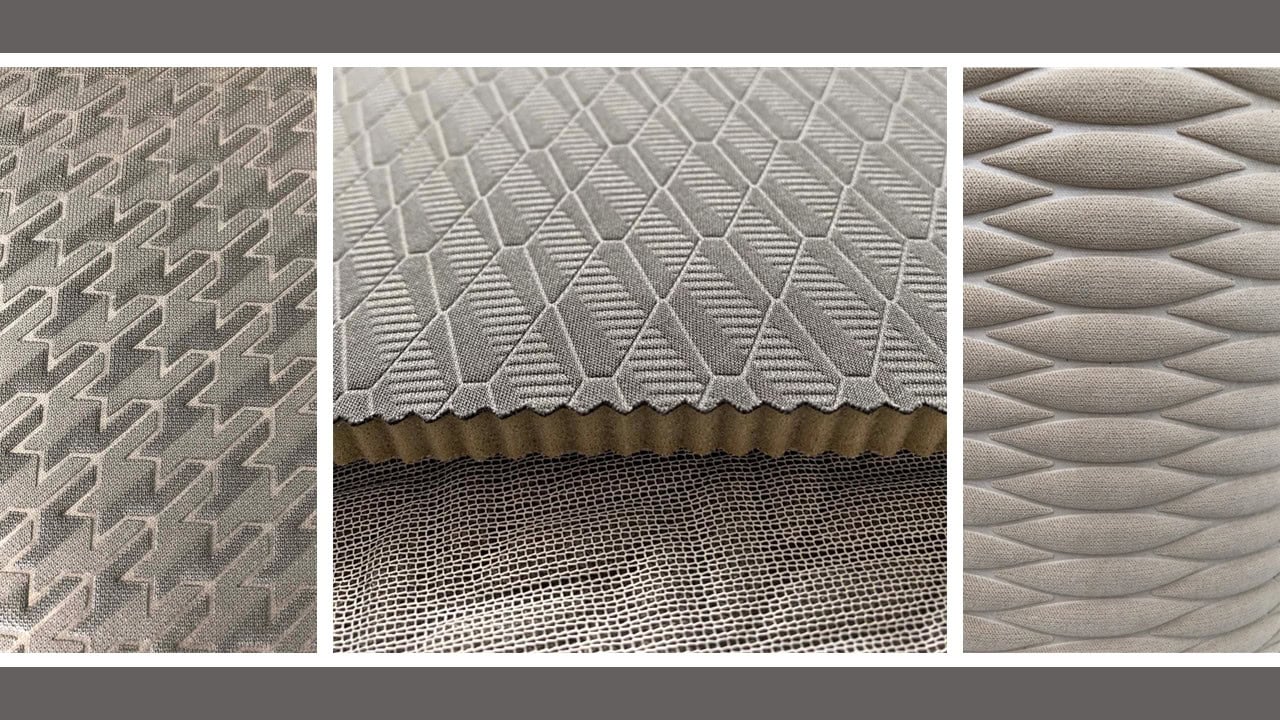

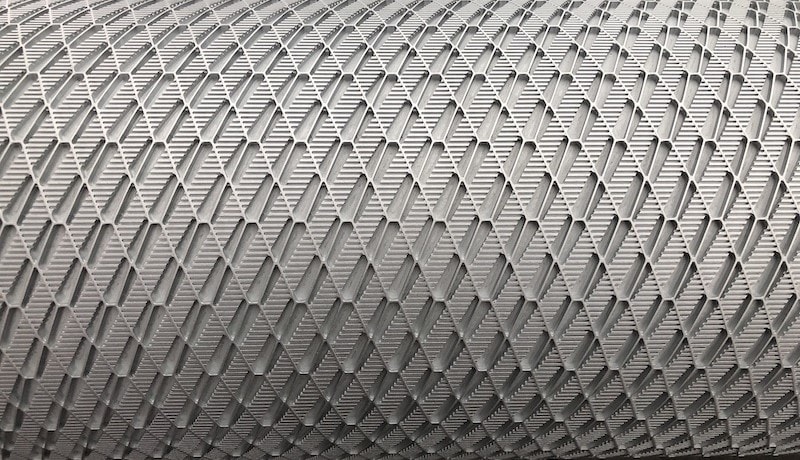

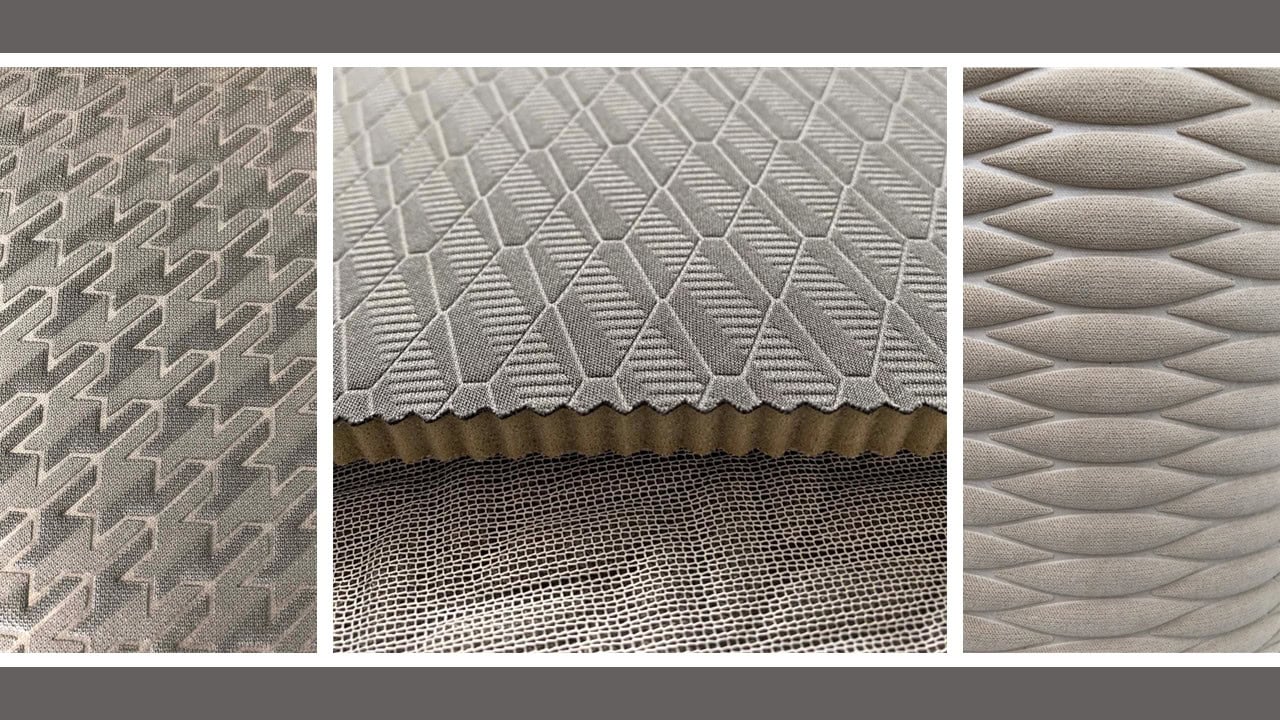

- Rollers and plates used in embossing can have a wide range of designs, from simple patterns like dots and lines to intricate and detailed designs.

- The surface of both types of tools may be engraved or embossed with the desired pattern, and the depth of the engraving can vary, affecting the texture and design impression on the fabric.

- The embossing rollers or plates are heated to the appropriate temperature depending on the type of used textile or laminated complex. The heat softens the fabric's surface fibers, making them more receptive to the embossing process.

- In case of roller embossing process, the material is fed through the embossing machine, passing between the heated embossing roller and a counter-pressure (receiving) roller.

- While embossing by plate technology, the material is pressed in-between engraved plate and counter plate

- The pressure between the rollers or plates ensures that the material is evenly pressed against the embossing tools, transferring the pattern onto the material’s surface.

Embossing technology has several advantages in automotive, textile, shoe and similar industries:

Added value: Embossing process is adding an additional value to the face material. Having just a few types of textiles material in various colors, you may create an infinite number of their versions, depending on market trends or customer’s demands. Their number depends only on your creativity.

Versatility: It can be used on a wide range of fabric types and already laminated complexes

Customization: Embossing tools can be engraved with custom designs, allowing for unique and branded fabric patterns.

Efficiency: The process (especially roller) is relatively fast and can be applied continuously, making it suitable for high-volume production.

Lamitoo offers you its unique know-how and experience in the field of plate and roller embossing process. We will help you implement this interesting process into your production portfolio, support you with product and design development, trainings of your production and development Teams.

We offer tailored embossing machinery, reliable solutions and individual approach.