Calendar lamination machines, also known as calender laminators, work on the principle of using heat and pressure to bond two or more materials together. These materials typically include a thermoplastic adhesive, often in the form of a film or powder, and a substrate, which can be textile, artificial leather or nonwoven. The machine has big roller that apply heat and pressure belt to ensure a secure bond between the layers.

Thermoplastic adhesives have the property of becoming soft and sticky when heated, making them suitable for this application. Examples of thermoplastic adhesives include modified polymers, such as Copolyamide, Copolyester, Polyolefin, Polyurethane, EVA, TPU etc

Such adhesives are available in many forms, as granulates, powders, nets, films and WEBs.

The heat from the big hot roller activates the adhesive, causing it to soften and bond with the other material. Pressure is also applied to ensure a secure bond. After lamination, the laminated material is allowed to cool. The adhesive cools and solidifies, creating a strong bond. In some cases, curing may be required to achieve the desired level of adhesion strength.

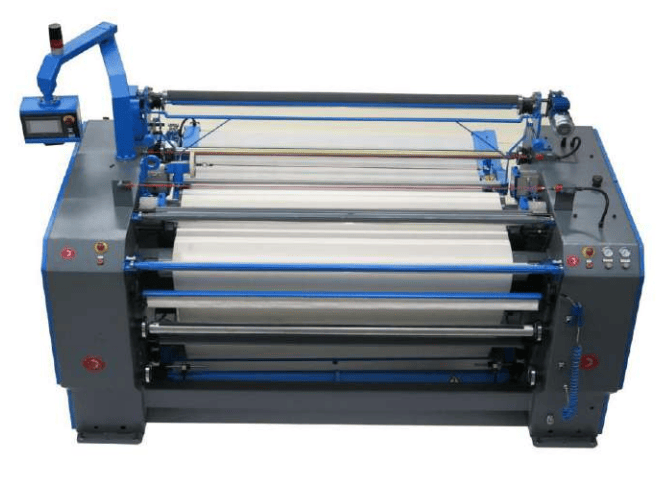

Machines offered by Lamitoo are very compact and modular. Depending on requested type, they’re available in various widths starting from 1600mm. Maximum heating temperature 250C.

They can be used for lamination, ironing and thermoprinting.

Machines can be equipped with such accessories as: